Merit

High thermal insulation structure and longtime cooling

Long distance and longtime transportation brought to you by the upgraded cooling performance

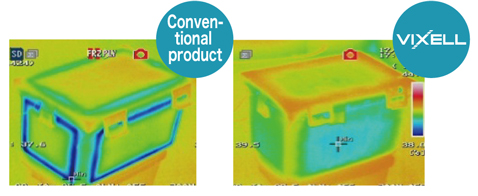

Seamless and integrally molded vacuum insulation housing (VIC- vacuum Insulated Case) is used for the thermal insulation layer, the key of the cooling box. Cold air leakage from joints has been a problem with conventional vacuum insulation panels (VIP)- it has been almost eliminated.

As a result, -75 ° C ± 15 ° C can be maintained for up to 18 days*.

* The vacuum insulated cooling box Type-L (AE-V 12 UXR) houses a dry ice thermal storage unit (AE-V 12 DXR) and 34 kg of dry ice is filled in the cooling box and storage box. Including only a simulated product of size 231 x 231 x 40 mm, measure the number of days the temperature is maintained at 30 ° C and -75 ° C ± 15 ° C.

Strength and durability

Prevents damage during shipping or transportation

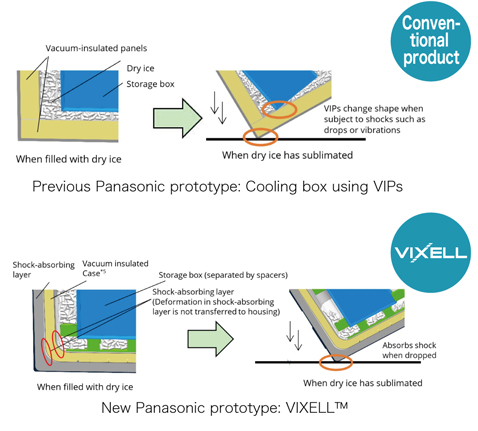

Unlike VIPs, whose insulation panels are covered with film, integrated VICs are strong and hard to break.

The resin that covers VIPs and VICs could be easily damaged by impact under low temperatures. VIXELL has been redesigned to reduce the damage when dropped. In addition, by adopting a structure in which the spacer supports the inner box, even if dry ice evaporates and decreases, the inner box can be prevented from moving and damage caused by dropping can be minimized.

Integrity

Reduce the risk of temperature excursions out of the cold zone

The VIC is equipped with a wireless vacuum sensor unit that uses contactless power supply technology, and the thermal insulation performance of the VIC can be easily checked by simply placing a box on a dedicated inspection board. General vacuum insulation products have a problem that damage during transportation or long-term use deteriorates the vacuum condition and reduces the insulation effect. VIXELL can be handled easily as the thermal insulation performance of the VIC can be checked before the usage.

Adaptation to a variety of temperature zones

Reduction of pre-cooling operation for boxes and refrigerants

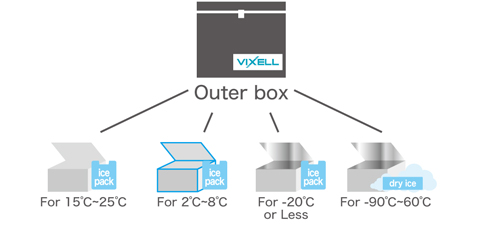

For the transportation of drugs, the appropriate transportation temperature is determined by the type of drugs and vaccines. Depending on the cooling box, it might be necessary to change the outer box for each set temperature range. In VIXELL, the outer box is shared with the "Thermal storage unit" of the inner box that stores the package to approx. -70°C, approx. -20°C, 2°C - 8°C, 15°C -25°C by simply changing the combination. It supports a wide range of temperatures. It also contributes to efficiency by saving resources.

IoT affinity

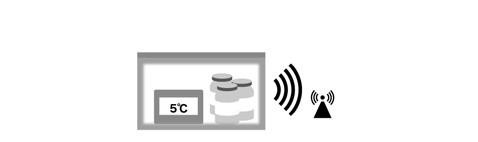

Wireless connection to IoT devices for monitoring without opening the box

Vacuum Insulated Case (VIC) transmits radio waves for communication, so it can also be linked with IoT devices. If a sensor such as temperature or GPS is installed in the box, the inside conditions can be monitored based on the communication information obtained without opening the box.