Approach to Environmental Initiatives

-Two material issues for realizing our Mission-

Our Mission is to “Powering a society where shared well-being and environmental sustainability thrive together.” With this in mind, we believe that our fundamental value is to play a leading role in transforming society into a sustainable one. At the same time, we have a responsibility to reduce our own environmental impact as we fulfill this role.

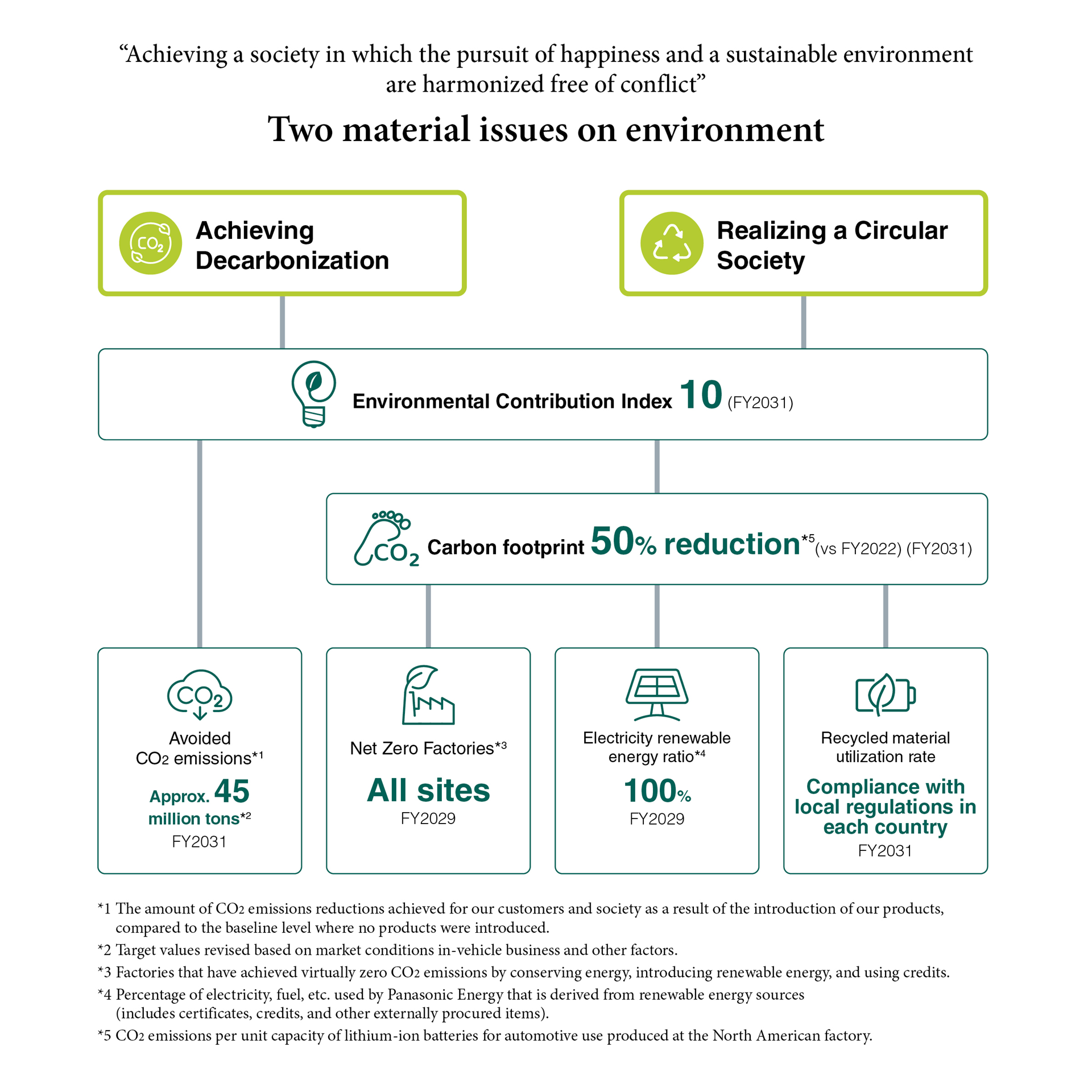

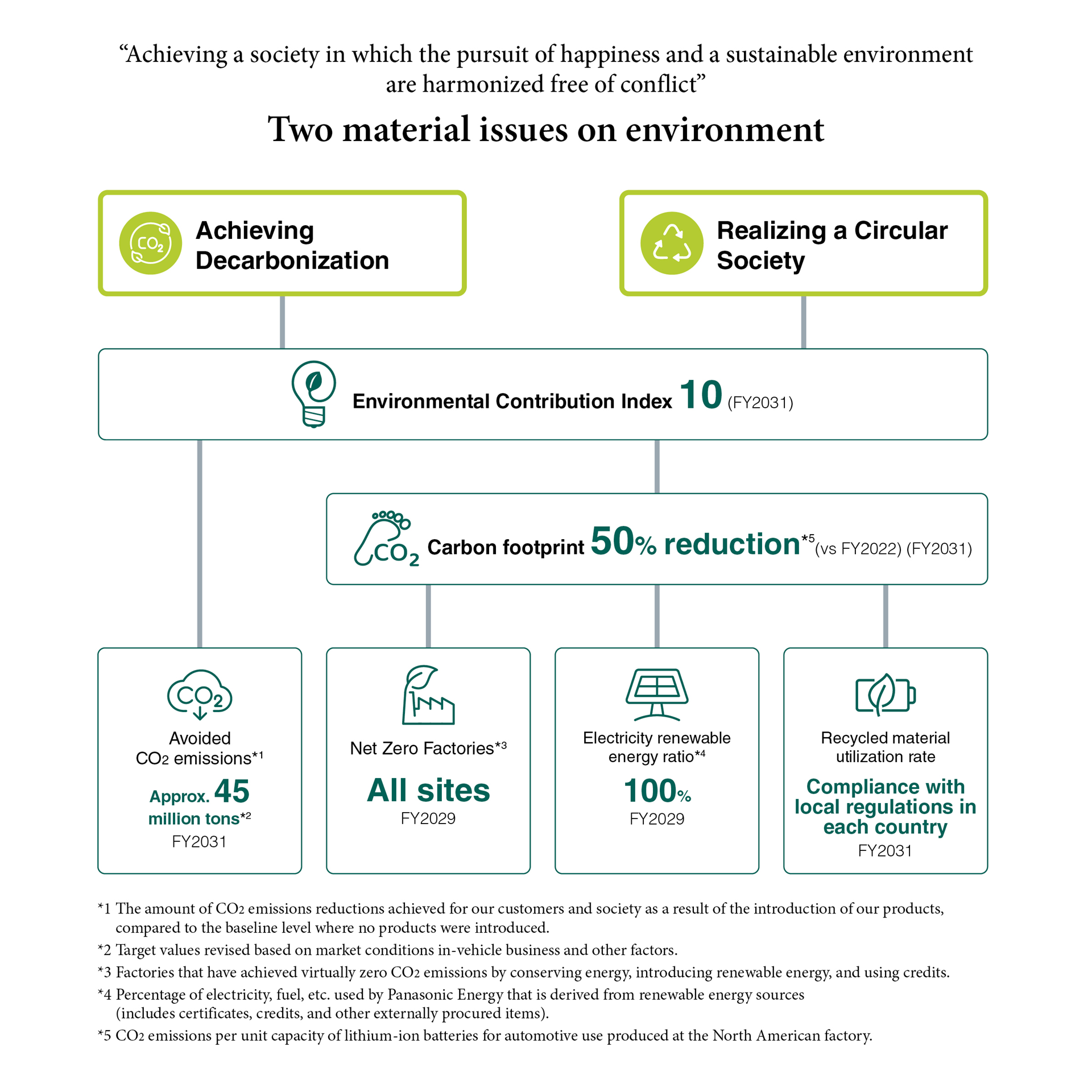

Based on our approaches and the expectations of our stakeholders, we have identified two material issues related to the environment: “Achieving decarbonization” and “Realizing a recycling-oriented society.” To maximize our contribution to the environment and minimize the environmental impact on each of these, we have set a total of six KPIs and their targets for fiscal 2031.

Approach to Environmental Initiatives

-Two material issues for realizing our Mission-

Our Mission is to “Powering a society where shared well-being and environmental sustainability thrive together.” With this in mind, we believe that our fundamental value is to play a leading role in transforming society into a sustainable one. At the same time, we have a responsibility to reduce our own environmental impact as we fulfill this role.

Based on our approaches and the expectations of our stakeholders, we have identified two material issues related to the environment: “Achieving decarbonization” and “Realizing a recycling-oriented society.” To maximize our contribution to the environment and minimize the environmental impact on each of these, we have set a total of six KPIs and their targets for fiscal 2031.

With respect to the KPIs associated with the material issue “achieving decarbonization,” to expand avoided CO2 emissions from our products and solutions that are used by end users, we have set a target of 45 million tons of avoided emissions in fiscal 2031. We also aim to reduce CO2 emissions during battery production, including procurement of raw materials, production, and product distribution. To this end, we are pursuing initiatives such as expanding the number of our own net-zero-CO2 factories and increasing our electricity renewable energy ratio, with the goal of cutting our carbon footprint in half by fiscal 2031 compared to fiscal 2022.

With respect to the KPIs associated with the material issue “realizing a recycling-oriented society,” we had previously set a recycling rate (in-house waste) KPI. However, now that almost all of our sites have achieved a recycling rate of 99% or more (with less than 1% of in-house waste going to landfill), we decided that this KPI was no longer necessary, since we had a system in place within the company that could be sustainably maintained. Therefore, starting this fiscal year, our only recycling KPI will be our recycled material utilization rate.

Going forward, we will strengthen our efforts to collect and recycle waste materials from the production process as well as used products, aiming to create a recycling loop through the reduction of natural resource consumption and waste. We believe that these initiatives will also contribute to reducing the carbon footprint of batteries.

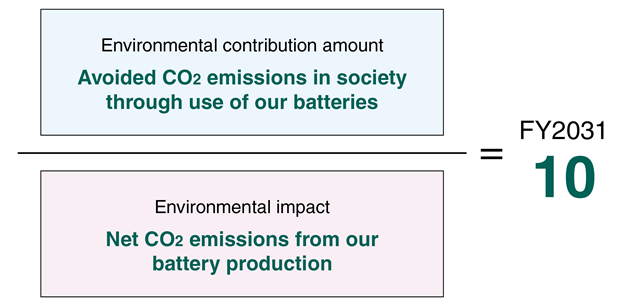

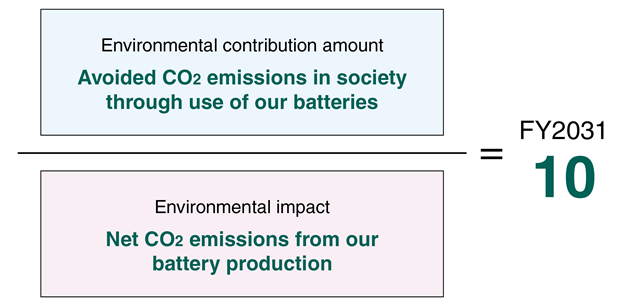

For these two material issues, we have established our own unique composite indicator, the "Environmental Contribution Index." This indicates the avoided CO2 emissions in society through use of our batteries divided by net CO2 emissions from our battery production. Our target value for fiscal 2031 is 10, which we aim to achieve by maximizing our contribution to the environment and minimizing the environmental impact of battery production.

Environmental Contribution Index calculation formula

With respect to the KPIs associated with the material issue “achieving decarbonization,” to expand avoided CO2 emissions from our products and solutions that are used by end users, we have set a target of 45 million tons of avoided emissions in fiscal 2031. We also aim to reduce CO2 emissions during battery production, including procurement of raw materials, production, and product distribution. To this end, we are pursuing initiatives such as expanding the number of our own net-zero-CO2 factories and increasing our electricity renewable energy ratio, with the goal of cutting our carbon footprint in half by fiscal 2031 compared to fiscal 2022.

With respect to the KPIs associated with the material issue “realizing a recycling-oriented society,” we had previously set a recycling rate (in-house waste) KPI. However, now that almost all of our sites have achieved a recycling rate of 99% or more (with less than 1% of in-house waste going to landfill), we decided that this KPI was no longer necessary, since we had a system in place within the company that could be sustainably maintained. Therefore, starting this fiscal year, our only recycling KPI will be our recycled material utilization rate.

Going forward, we will strengthen our efforts to collect and recycle waste materials from the production process as well as used products, aiming to create a recycling loop through the reduction of natural resource consumption and waste. We believe that these initiatives will also contribute to reducing the carbon footprint of batteries.

For these two material issues, we have established our own unique composite indicator, the "Environmental Contribution Index." This indicates the avoided CO2 emissions in society through use of our batteries divided by net CO2 emissions from our battery production. Our target value for fiscal 2031 is 10, which we aim to achieve by maximizing our contribution to the environment and minimizing the environmental impact of battery production.

Environmental Contribution Index calculation formula