Achieving Decarbonization

Achieving Decarbonization

Policy

Our Mission is to “Powering a society where shared well-being and environmental sustainability thrive together.” and therefore, responding to climate change, an urgent issue common to all humankind, is our most important challenge. To address this challenge, we will work to increase avoided CO2 emissions (when our products and solutions are used by end-users) and reduce CO2 emissions during battery production, including procurement of raw materials, production, and product distribution. By increasing our environmental contribution and reducing our environmental impact, we are working together as a Group and in collaboration with our stakeholders to maximize the value we provide.

Increasing avoided CO2 emissions

Contribution to the environment through our products

Panasonic Energy is working to increase avoided CO2 emissions through mobility electrification and other initiatives to contribute to the environment through the spread of our products and solutions.

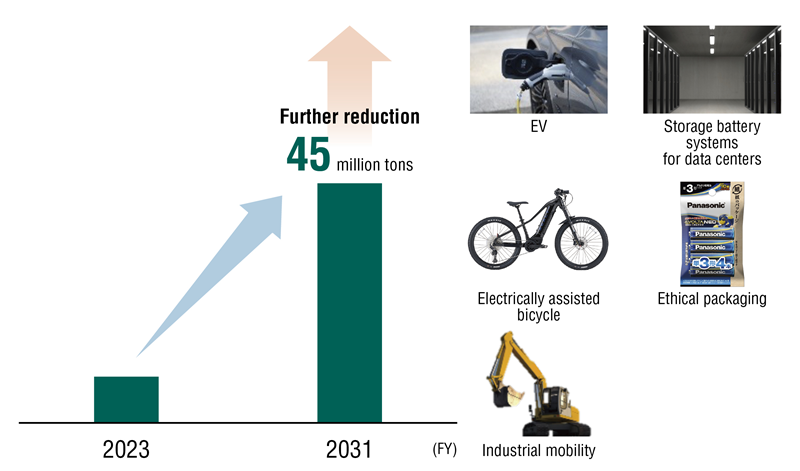

To increase avoided CO2 emissions, we are looking beyond products like our Li-ion batteries for vehicles and electrically assisted bicycles that reduce CO2 emissions through product electrification, and are now considering products that can be expected to reduce CO2 emissions through the energy saving benefits of replacing conventional products, including our storage battery systems for data centers*1, whose avoided emissions we quantified for the first time in fiscal 2025. This brings our avoided CO2 emissions to approximately 16 million tons in fiscal 2025.

By fiscal 2031, we aim to achieve avoided CO2 emissions of 45 million tons by continuing to enhance our production capacity and expanding our products and solutions into areas such as industrial mobility, where electrification is progressing, thereby contributing to the decarbonization of society.

*1 Reduction in the amount of electricity supplied over the lifetime of use by replacing centralized power sources with distributed power sources

Expanding contribution through the wider adoption of products and solutions that help achieve decarbonization

Initiatives toward international standardization of avoided CO2 emissions

Achieving a carbon-neutral society by 2050 will require a significant reduction in greenhouse gas (GHG) emissions across society as a whole. In this context, companies are expected not only to reduce GHG emissions within their own value chains but also to help realize carbon neutrality by manufacturing and expanding the use of products that contribute to decarbonization for their customers and for society at large. However, under existing GHG emission indicators, the production of products that contribute to decarbonization may result in an increase in a company’s reported GHG emissions, meaning that the company’s contribution to society’s overall decarbonization is not properly reflected.

Avoided CO2 emissions are an indicator that quantifies how much a company’s products and solutions have reduced CO2 emissions for customers and society. This metric can capture the contribution of a company’s products to decarbonization—something that is difficult to express under conventional GHG emission indicators. At present, however, there is no unified standard for calculating and disclosing avoided CO2 emissions, and awareness of the concept remains limited.

For this reason, as a member of the Panasonic Group, we are actively involved in efforts to establish international standards for avoided CO2 emissions, such as contributing to the development of guidance by the WBCSD*2 and to the creation of international standards at the IEC*3. We are working to develop rational calculation methods and are committed to appropriate information disclosure based on internationally recognized rules.

Going forward, we will continue to develop and promote products and solutions that contribute to decarbonization, reduce society’s overall GHG emissions, and work toward powering a society where shared well-being and environmental sustainability thrive together.

*2 The World Business Council for Sustainable Development

*3 International Electrotechnical Commission

Relationship between the Inflation Reduction Act (IRA) and avoided emissions

The IRA is the largest investment the U.S. has ever made to tackle climate change. *4 The law is designed to reduce CO2 emissions by 21 billion tons between 2023 and 2050 and to prevent $5.6 trillion in global economic losses from climate change. *5

The IRA provides tax credits and subsidies for industries that contribute to energy security and climate actions. Panasonic Energy benefits from a tax credit of $35/kWh on our automotive batteries produced and delivered in North America. *6 We believe that this tax credit was made possible by our efforts to promote the spread of EVs in society and contribute to avoided CO2 emissions through the manufacture of automotive batteries. As indicated, the amount of our tax credit under the IRA is proportional to the amount of avoided CO2 emissions from our automotive batteries. We believe this is an example where our contribution to decarbonization through automotive batteries has been recognized by society in terms of monetary value.

*4 As of August 2022

*5 https://home.treasury.gov/news/featured-stories/the-inflation-reduction-acts-benefits-and-costs

*6 Section 45X

Reducing CO2 emissions during battery production

What we do

While contributing to avoided CO2 emissions in society through the widespread use of our products and solutions, we are also working to reduce CO2 emissions during battery production, including procurement of raw materials, production, and product distribution.

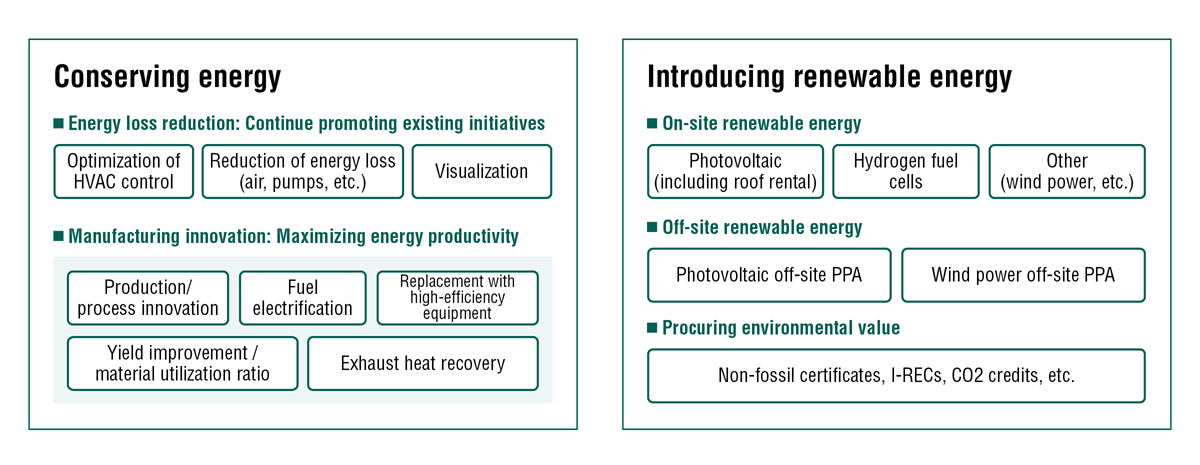

In our battery production process, we are working to reduce our environmental impact by both conserving energy and introducing renewable energy. Using environmental certificates and credits, we aim to achieve Net Zero Factories*7 at all sites by fiscal 2029.

Achieved Net Zero Factory status at 17 global sites, including all sites in Japan (as of September 2024)

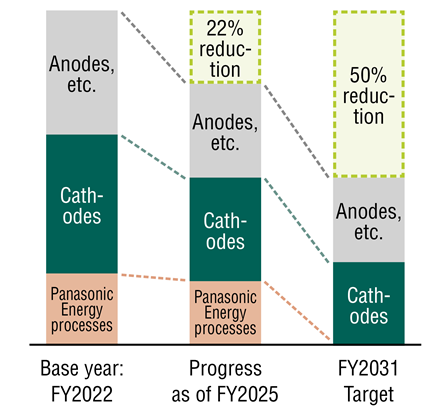

Furthermore, to reduce CO2 emissions across the entire supply chain, we are strengthening our reduction efforts both through internal initiatives and in cooperation with our suppliers with the goal of cutting our carbon footprint (CFP) per unit battery capacity in half*8 by fiscal 2031 compared to fiscal 2022.

Progress and targets for CFP reduction

*7 Factories that have achieved net zero CO2 emissions by conserving energy, introducing renewable energy, and using credits

*8 CO2 emissions per unit capacity of lithium-ion batteries for automotive use produced at the North American factories.

Initiatives in the battery production process

Conserving energy

Our battery production processes consume large amounts of energy through the use of equipment such as dryers and air-conditioning systems. To reduce environmental impact, we are implementing energy-saving measures such as optimizing air-conditioning control and reducing energy loss, while also driving manufacturing innovation through production and process innovations, as well as electrification and conversion of fuel sources.

As a specific example of reducing energy intensity by improving production efficiency, our Kaizuka Factory established optimal drying conditions in the electrode plate production process using scientific methods, thereby increasing coating speed. This new process is scheduled to be deployed at major domestic and overseas lithium-ion battery production sites starting in fiscal 2026.

In 2023, we established the CO2 subcommittee to promote cross-site initiatives. The subcommittee shares improvement cases company-wide to maximize energy-saving effects. In fiscal 2025, members of the subcommittee conducted energy-saving assessments at three domestic sites, generating ideas expected to reduce CO2 emissions by approximately 3,500 tons. Moving forward, we plan to implement these measures more broadly, including at overseas sites.

CO2 subcommittee meeting

Introducing renewable energy

As of September 2024, we have achieved Net Zero Factory status at 17 sites worldwide. Our next step is to increase our in-house renewable energy self-sufficiency rate*9 without relying on environmental certificates.

At the Nishikinohama Factory, when installing photovoltaic power generation equipment across the entire roof, we adopted a new installation method that eliminated the need for large-scale modifications to the factory’s substation. This reduced construction costs, shortened construction time, and improved our in-house renewable energy self-sufficiency rate. These initiatives were highly evaluated, earning the Minister of Economy, Trade and Industry Award in the Implementation Activities Category of the New Energy Awards 2023 hosted by the New Energy Foundation, in collaboration with FD Corporation and Panasonic Holdings Corporation. Other sites have begun installing photovoltaic power generation equipment not only on rooftops but also in parking lots. These solar carports provide shelter from rain and sun, improving employee comfort and contributing to better workplace amenities.

Going forward, we will consider expanding the introduction of renewable energy globally, taking into account the characteristics of each region.

Panasonic Energy Wuxi

Panasonic Energy Higashiura

*9 An indicator showing the proportion of renewable energy supplied from in-house power generation facilities. Does not include certificate-only procurement

Introduction of off-site corporate PPAs

In addition to on-site photovoltaic power generation (including on-site PPAs), we have introduced off-site corporate PPAs*10 for solar and onshore wind power. Starting in April 2025, through our electricity retail subsidiary Panasonic Operational Excellence Company, we entered into an off-site corporate PPA with Kyuden Mirai Energy Corporation to procure renewable electricity from geothermal power. Because geothermal power can generate a stable supply of energy without being affected by weather conditions, this initiative will increase the in-house renewable energy self-sufficiency rate for our domestic electricity use from approximately 15% to about 30%*11. It will also yield an annual CO2 reduction effect of around 50,000 tons—the equivalent of the annual CO2 absorption of approximately 56 km2 of forest (about 4,300 times the size of Koshien Stadium) *12.

Geothermal

Onshore wind

Solar

*10 A contractual arrangement in which the owner of a renewable energy source (including developers, investors, and others) and a purchaser of electricity (such as an end user) enter into an agreement to buy and sell renewable electricity at a pre-agreed-upon price and for a pre-agreed-upon term. Under this arrangement, renewable electricity generated at an off-site renewable energy facility located away from the point of consumption is supplied to the purchaser via the general power grid. (Source: Ministry of the Environment/Mizuho Research & Technologies, “About Off-site Corporate PPAs” *Japanese-language document only)

*11 Based on calculations using the actual electricity consumption at all of our domestic sites in 2024.

*12 Well-maintained, 36 to 40-year-old artificial cedar forests. (Data source: Forestry Agency website)

Initiatives to utilize next-generation energy

Panasonic Energy is promoting the use of hydrogen as a next-generation energy source that contributes to the reduction of CO2 emissions in society. We have introduced pure hydrogen fuel cells at our Nishikinohama Factory in Japan and at Panasonic Energy Wuxi, China. The Nishikinohama Factory in particular is working to efficiently utilize renewable energy through optimal control of energy that is from the combination of photovoltaic power generation and storage batteries. At the 2025 Osaka-Kansai Expo, as part of an event under the theme "Change the Future! Hydrogen Week," we offered off-site visit tours*13 in partnership with Iwatani Corporation and Kawasaki Heavy Industries. Going forward, we will continue to contribute to decarbonization by utilizing next-generation energy.

Nishikinohama Factory

Hydrogen tank

*13 Expo-related experiences and tours are accessible not only in Yumeshima, the site of the Expo, but also across Osaka Prefecture and other areas in the Kansai region

Utilization of reused batteries

To minimize environmental impact, we are promoting the reuse of spent batteries.

At our Tokushima Factory, which began operating as a Net Zero Factory in 2023, we are conducting demonstration tests on the installation of storage battery containers that utilize reused batteries. Specifically, we repurpose used batteries collected from data centers as high-voltage system modules, store electricity generated from solar panels, and use them to power nighttime lighting and other applications.

Going forward, we will promote the use of reused batteries for storage battery containers to expand the adoption of renewable energy, reduce CO2 emissions associated with product disposal, and lower environmental impact through both CO2 reductions and waste minimization.

Storage battery container (Tokushima Factory)

Initiatives in raw material procurement

A large portion of the CO2 emissions (carbon footprint) associated with battery production occurs upstream of our manufacturing processes—in resource extraction, raw material processing, and logistics. In response and to reduce environmental impact across the entire supply chain, we have set a target*14 to cut the carbon footprint per unit of battery capacity by half from fiscal 2022 levels by fiscal 2031. This includes working with suppliers to reduce CO2 emissions in production processes, increasing the ratio of locally sourced materials, and reducing CO2 emissions in logistics. In fiscal 2025, these efforts resulted in a 22% reduction compared to fiscal 2022.

*14 CO2 emissions per unit capacity of lithium-ion batteries for automotive use produced at the North American factories.

Initiatives with suppliers

We work closely with suppliers to reduce CO2 emissions throughout all processes for the materials we use, from resource extraction to raw material processing and logistics. Through initiatives such as our annual Partners’ Meeting, we ensure suppliers understand our policy toward 2030 and establish a framework for collaboration under a shared understanding to reduce CO2 emissions. As part of these efforts, based on the calculated CFP for batteries, we set reduction targets for key components and materials that will have the greatest impact. We hold frequent discussions with suppliers to advance concrete measures such as introducing high-efficiency equipment, optimizing production processes, adopting renewable energy, and procuring low-CFP raw materials.

Across the materials value chain, specifically the resource extraction and raw-material processing stages, and with a particular focus on critical minerals such as nickel and lithium, we will identify suppliers with low CO2 emissions (for example, those with a high share of renewable-energy use) and position them as strategic medium- to long-term procurement partners. Working together with these partners, we will promote the introduction of renewable energy, adopt EV trucks at mining sites, use recycled materials, develop low-CO2-emission processes, reduce energy consumption, and carry out tree-planting and related activities.

Partners’ Meeting 2024

Initiatives to increase the ratio of locally sourced materials

Focusing on North America as a priority region, we are working to reduce the CFP of our batteries by increasing the ratio of locally sourced materials. For natural graphite, in October 2022, we signed a memorandum of understanding for an offtake agreement (long-term supply agreement) with Nouveau Monde Graphite of Canada. Since then, we have advanced technological development and process optimization to meet our product specifications and quality standards, and in February 2024, we made an equity investment in the company and signed a seven-year offtake agreement. Canada’s high share of electricity from renewable sources such as hydropower, combined with its integrated production system from resource extraction to anode materials, enables procurement of anode materials with significantly reduced CO2 emissions.

For synthetic graphite, we have entered into a long-term supply agreement with Novonix, and since 2025, we have been conducting joint development for supply from the company’s Tennessee, U.S. factory to our North American factories. The company’s continuous graphitization furnace technology is expected to reduce CO2 emissions during synthetic graphite production compared to conventional methods. In addition to increasing the local procurement ratio in North America, we are also taking a strategic approach to reducing the environmental impact of our supply chain.

Furthermore, we have signed a long-term supply agreement with H&T Recharge for battery can cases. H&T supplies can cases for lithium-ion battery production from within the premises of our Nevada, U.S. Factory. This on-site supply structure not only increases the local procurement ratio in North America but is also expected to reduce CO2 emissions associated with logistics by shortening transport distances for the can cases.

In addition, we are actively promoting the use of raw materials recovered from used lithium-ion batteries, further contributing to CO2 emission reductions.

NOVONIX continuous graphitization furnace (as of February 2024)

Initiatives in product distribution

Panasonic Energy is also promoting initiatives to reduce CO2 emissions in product distribution. In Japan, in addition to optimizing transportation methods and transportation routes, we have partnered with EcoTruck Co., Ltd on proof-of-concept trials to replace conventional diesel-fueled trucks with trucks fueled with biogas*15, which can be regarded as having zero CO2 emissions during driving. We plan to roll out a partial deployment in fiscal 2026, and then, in the future, expand the rollout from product distribution to the procurement and distribution of raw materials.

Biogas truck

*15 Purified methane derived from biomass