Pursuit of Quality and Product Safety

Pursuit of Quality and Product Safety

Policy

As the level of quality demanded by society increases, product safety and superior quality are important elements that demonstrate our brand power. We have positioned quality as the driving force behind the advancement of our business, defining quality as “our competitive edge to win customer trust and satisfaction,” and setting our quality policy as “maximizing our competitive edge to achieve 100% customer satisfaction.” Maximizing competitiveness requires maximizing the sum of the competitiveness of all job functions, including design, manufacturing, quality, sales, among others, and we are promoting initiatives from the following perspectives to maximize our competitiveness.

Defense: Initiatives to make existing frameworks and processes more robust*1.

Offense: New initiatives aimed at advancing our business

Foundation: Initiatives that form the basis for business promotion

Through these activities, we aim to eliminate all serious product incidents.

*1 The strength of a system or machine against external forces.

Policy

As the level of quality demanded by society increases, product safety and superior quality are important elements that demonstrate our brand power. We have positioned quality as the driving force behind the advancement of our business, defining quality as “our competitive edge to win customer trust and satisfaction,” and setting our quality policy as “maximizing our competitive edge to achieve 100% customer satisfaction.” Maximizing competitiveness requires maximizing the sum of the competitiveness of all job functions, including design, manufacturing, quality, sales, among others, and we are promoting initiatives from the following perspectives to maximize our competitiveness.

Defense: Initiatives to make existing frameworks and processes more robust*1.

Offense: New initiatives aimed at advancing our business

Foundation: Initiatives that form the basis for business promotion

Through these activities, we aim to eliminate all serious product incidents.

*1 The strength of a system or machine against external forces.

Quality assurance system

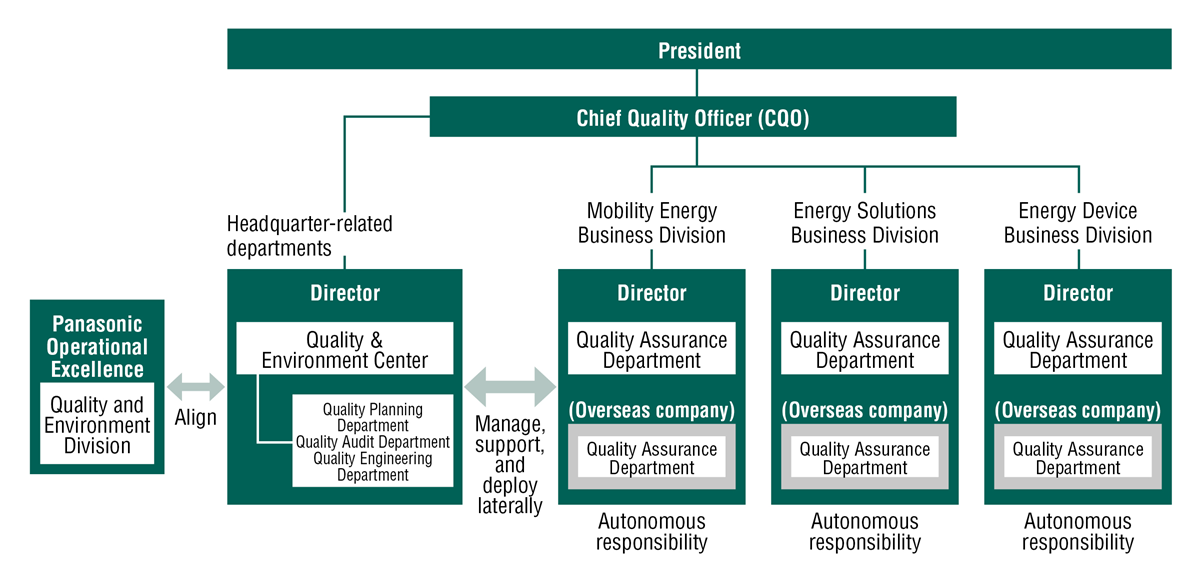

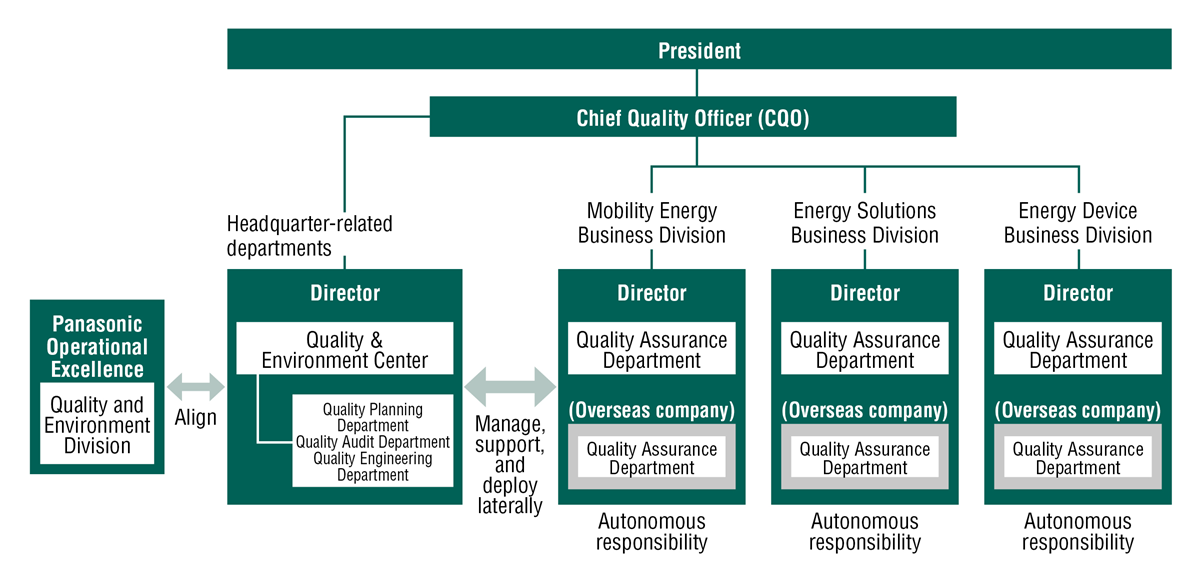

The Chief Quality Officer (CQO) is the officer in charge of quality, directly reporting to the President who is responsible for managing the Company. For each business division, a quality manager reports to the Director of the respective business division and autonomously promotes quality assurance. Quality manager meetings and liaison meetings are held monthly among each business division and Headquarters -related departments to share information on quality losses and important quality issues, and to discuss and decide on policies and specific measures to address common issues of the Panasonic Energy Group. Furthermore, for major issues that could affect the entire Panasonic Group, the Center works closely with the Quality and Environment Division of Panasonic Operational Excellence to discuss and address the issue. The Quality & Environment Center of the Company formulates quality policies, checks quality status, assists each business division in addressing quality issues, and disseminates quality information, recurrence prevention measures, best practices, and other information across the company. In addition, the center implements a variety of educational and awareness-raising measures to create a corporate culture that places the highest priority on safety and quality and complies with laws, and monitoring and restraint whether the quality management systems of the business divisions are being operated appropriately.

Our quality assurance system

Quality assurance system

The Chief Quality Officer (CQO) is the officer in charge of quality, directly reporting to the President who is responsible for managing the Company. For each business division, a quality manager reports to the Director of the respective business division and autonomously promotes quality assurance. Quality manager meetings and liaison meetings are held monthly among each business division and Headquarters -related departments to share information on quality losses and important quality issues, and to discuss and decide on policies and specific measures to address common issues of the Panasonic Energy Group. Furthermore, for major issues that could affect the entire Panasonic Group, the Center works closely with the Quality and Environment Division of Panasonic Operational Excellence to discuss and address the issue. The Quality & Environment Center of the Company formulates quality policies, checks quality status, assists each business division in addressing quality issues, and disseminates quality information, recurrence prevention measures, best practices, and other information across the company. In addition, the center implements a variety of educational and awareness-raising measures to create a corporate culture that places the highest priority on safety and quality and complies with laws, and monitoring and restraint whether the quality management systems of the business divisions are being operated appropriately.

Our quality assurance system

Activities to ensure product quality and safety

The batteries we sell are devices that store high-density energy in large capacities, and their safe and reliable use is an absolute necessity. In particular, Li-ion batteries, our main products, have inherent risks that can lead to smoke and fire; these risks include high energy density, which can cause the battery to reach high temperatures in the event of a short circuit, and the use of flammable liquid as an electrolyte. Given these product characteristics, we issued a recall notice to prevent unsafe accidents, which caused great concern and inconvenience to our customers and other concerned parties.

Based on these reflections and lessons learned, we continue to promote quality innovation, including making quality assurance processes more robust, enhancing safety design and manufacturing, and fostering a quality-oriented culture, to ensure high quality standards with the utmost priority on product safety, and we had no serious product incidents in fiscal 2025. We will continue to work toward the goal of zero incidents going forward.

Making quality assurance processes more robust

To establish a quality assurance process, we have built and operate a quality management system that complies with ISO 9001, IATF 16949, and other global standards in each business division, and regularly check its effectiveness through internal and external audits. We also conduct our own quality audits of business divisions through our Quality & Environment Center to identify weaknesses and issues in terms of quality assurance and compliance, and work with business divisions to make improvements toward better quality assurance through the horizontal application of best practices. In fiscal 2026, we will establish a new Quality Audit Department within the Center to systematically strengthen these activities. The Quality & Environment Center itself also undergoes functional audits by Panasonic Operational Excellence to identify and improve issues in its governance functions, thereby working to ensure quality assurance processes Companywide through operations and monitoring.

Strengthening product safety design and manufacturing

The environment, fields, and devices in which batteries are used are changing with the evolution of society. To address these changes in the design process, we identify and verify risks together with our customers (B-to-B and B-to-C) and suppliers of parts and materials. The identified risks are then fed back to product design, component design, and process design to confirm their validity as key verification items in the development process. To prevent problems in the manufacturing process as well, we identify risks and take countermeasures by visualizing key data (DX) and FMEA*2 in all processes from source to shipping, thereby bolstering management. We are also committed to developing human resources capable of putting these initiatives into practice by providing training in quality tools and statistical management methods, as well as support for hands-on activities.

*2 Failure Mode and Effects Analysis

New product development flow

Fostering a quality-oriented culture and developing human resources

We regularly hold various training sessions and events for all employees to foster a culture of placing the highest priority on product quality and compliance. Especially during "Quality Month," which is held every November, we work to raise awareness and foster a quality-oriented culture through messages from executives, discussions of quality themes at workplace meetings, and passing on the details of and lessons learned from past product incidents.

Furthermore, in order develop human resources who can achieve the quality we aim for, we are building and implementing an education system according to rank and skill and hosting various events, among other activities. For technical employees, we provide training in the basics of statistical quality management methods as well as the fundamentals of quality. For young quality personnel, we have established training courses that enable intensive learning and are working to enhance their development.

In fiscal 2025, we carried out the following initiatives.

1. Management executives communication and employee interaction

When management executives announce policies at the beginning of the fiscal year and results at the end of the fiscal year, they share quality-related policies and results with employees, leading to the encouragement of Company-wide quality improvement. During “Quality Month” in November, the CEO, CTO/CQO, Director of the Quality and Environment Center, and Directors of each business division delivered messages on the importance of quality, in order to reaffirm that quality is an absolute requirement for our business.

We also held a Company-wide technology symposium, with a corner devoted to displaying posters from the quality control departments, where we promoted communication across departmental boundaries and deepened mutual understanding for improving quality through reports on activities to improve design and manufacturing quality and examples of tool utilization. Management executives also participated in the symposium, where employees from the quality control departments exchanged opinions directly with the executives in front of the presentation posters on topics such as "how to improve quality."

2. Product safety forum

We hold a Product safety forum with the aim of raising employee awareness of product safety. At past forums, experts from Panasonic Energy have reviewed past quality issues and given technical lectures on product safety. In fiscal 2025, for the first time, we invited an external expert from the National Research Institute of Fire and Disaster of the Fire and Disaster Management College under the jurisdiction of the Fire and Disaster Management Agency to give a lecture entitled "Fire Investigation for Firefighters." The lecture covered a range of notable fires that have occurred in recent years, focusing mainly on those related to batteries. The speaker introduced case studies of both large- and small-scale incidents, and then spoke about the issues faced on-site and the importance of cooperation between manufacturers and fire departments and product safety. After witnessing the efforts on the front lines of firefighting, attendees made comments like "This reaffirmed the importance of reliable manufacturing and our responsibility for product safety," and "Seeing the impact of fire has increased my sense of responsibility and awareness of risk management," indicating the value of this forum for raising awareness of quality and safety.

Product safety forum

3. Quality compliance learning

We worked to strengthen compliance learning in response to the quality compliance misconduct issues identified within the Panasonic Group in 2024. All employees were issued a copy of the Panasonic Group's "Compliance Essentials " booklet, from which they can learn about "Understanding Actual Conditions," "Recognizing Misconceptions," and "Consciously Acting Correctly," to inspire them to think of compliance as something that concerns them personally. In addition, in light of certification-related irregularities that have arisen, we conducted e-learning sessions and workplace discussion meetings focused on regulatory and certification misconduct utilizing an educational manga. We will continue to work to foster a culture of compliance in the next fiscal year and beyond.

Activities to ensure product quality and safety

The batteries we sell are devices that store high-density energy in large capacities, and their safe and reliable use is an absolute necessity. In particular, Li-ion batteries, our main products, have inherent risks that can lead to smoke and fire; these risks include high energy density, which can cause the battery to reach high temperatures in the event of a short circuit, and the use of flammable liquid as an electrolyte. Given these product characteristics, we issued a recall notice to prevent unsafe accidents, which caused great concern and inconvenience to our customers and other concerned parties.

Based on these reflections and lessons learned, we continue to promote quality innovation, including making quality assurance processes more robust, enhancing safety design and manufacturing, and fostering a quality-oriented culture, to ensure high quality standards with the utmost priority on product safety, and we had no serious product incidents in fiscal 2025. We will continue to work toward the goal of zero incidents going forward.

Making quality assurance processes more robust

To establish a quality assurance process, we have built and operate a quality management system that complies with ISO 9001, IATF 16949, and other global standards in each business division, and regularly check its effectiveness through internal and external audits. We also conduct our own quality audits of business divisions through our Quality & Environment Center to identify weaknesses and issues in terms of quality assurance and compliance, and work with business divisions to make improvements toward better quality assurance through the horizontal application of best practices. In fiscal 2026, we will establish a new Quality Audit Department within the Center to systematically strengthen these activities. The Quality & Environment Center itself also undergoes functional audits by Panasonic Operational Excellence to identify and improve issues in its governance functions, thereby working to ensure quality assurance processes Companywide through operations and monitoring.

Strengthening product safety design and manufacturing

The environment, fields, and devices in which batteries are used are changing with the evolution of society. To address these changes in the design process, we identify and verify risks together with our customers (B-to-B and B-to-C) and suppliers of parts and materials. The identified risks are then fed back to product design, component design, and process design to confirm their validity as key verification items in the development process. To prevent problems in the manufacturing process as well, we identify risks and take countermeasures by visualizing key data (DX) and FMEA*2 in all processes from source to shipping, thereby bolstering management. We are also committed to developing human resources capable of putting these initiatives into practice by providing training in quality tools and statistical management methods, as well as support for hands-on activities.

*2 Failure Mode and Effects Analysis

New product development flow

Fostering a quality-oriented culture and developing human resources

We regularly hold various training sessions and events for all employees to foster a culture of placing the highest priority on product quality and compliance. Especially during "Quality Month," which is held every November, we work to raise awareness and foster a quality-oriented culture through messages from executives, discussions of quality themes at workplace meetings, and passing on the details of and lessons learned from past product incidents.

Furthermore, in order develop human resources who can achieve the quality we aim for, we are building and implementing an education system according to rank and skill and hosting various events, among other activities. For technical employees, we provide training in the basics of statistical quality management methods as well as the fundamentals of quality. For young quality personnel, we have established training courses that enable intensive learning and are working to enhance their development.

In fiscal 2025, we carried out the following initiatives.

1. Management executives communication and employee interaction

When management executives announce policies at the beginning of the fiscal year and results at the end of the fiscal year, they share quality-related policies and results with employees, leading to the encouragement of Company-wide quality improvement. During “Quality Month” in November, the CEO, CTO/CQO, Director of the Quality and Environment Center, and Directors of each business division delivered messages on the importance of quality, in order to reaffirm that quality is an absolute requirement for our business.

We also held a Company-wide technology symposium, with a corner devoted to displaying posters from the quality control departments, where we promoted communication across departmental boundaries and deepened mutual understanding for improving quality through reports on activities to improve design and manufacturing quality and examples of tool utilization. Management executives also participated in the symposium, where employees from the quality control departments exchanged opinions directly with the executives in front of the presentation posters on topics such as "how to improve quality."

2. Product safety forum

We hold a Product safety forum with the aim of raising employee awareness of product safety. At past forums, experts from Panasonic Energy have reviewed past quality issues and given technical lectures on product safety. In fiscal 2025, for the first time, we invited an external expert from the National Research Institute of Fire and Disaster of the Fire and Disaster Management College under the jurisdiction of the Fire and Disaster Management Agency to give a lecture entitled "Fire Investigation for Firefighters." The lecture covered a range of notable fires that have occurred in recent years, focusing mainly on those related to batteries. The speaker introduced case studies of both large- and small-scale incidents, and then spoke about the issues faced on-site and the importance of cooperation between manufacturers and fire departments and product safety. After witnessing the efforts on the front lines of firefighting, attendees made comments like "This reaffirmed the importance of reliable manufacturing and our responsibility for product safety," and "Seeing the impact of fire has increased my sense of responsibility and awareness of risk management," indicating the value of this forum for raising awareness of quality and safety.

Product safety forum

3. Quality compliance learning

We worked to strengthen compliance learning in response to the quality compliance misconduct issues identified within the Panasonic Group in 2024. All employees were issued a copy of the Panasonic Group's "Compliance Essentials " booklet, from which they can learn about "Understanding Actual Conditions," "Recognizing Misconceptions," and "Consciously Acting Correctly," to inspire them to think of compliance as something that concerns them personally. In addition, in light of certification-related irregularities that have arisen, we conducted e-learning sessions and workplace discussion meetings focused on regulatory and certification misconduct utilizing an educational manga. We will continue to work to foster a culture of compliance in the next fiscal year and beyond.